In the broad field of glass technology, photovoltaic (PV) glass and float glass are two distinct products. Each plays an indispensable role in solar energy utilization and in various fields such as construction and automotive industries. So, what exactly differentiates solar PV glass from float glass? This article will compare these two types of glass in terms of their uses, materials, manufacturing methods, and other aspects.

1. Uses

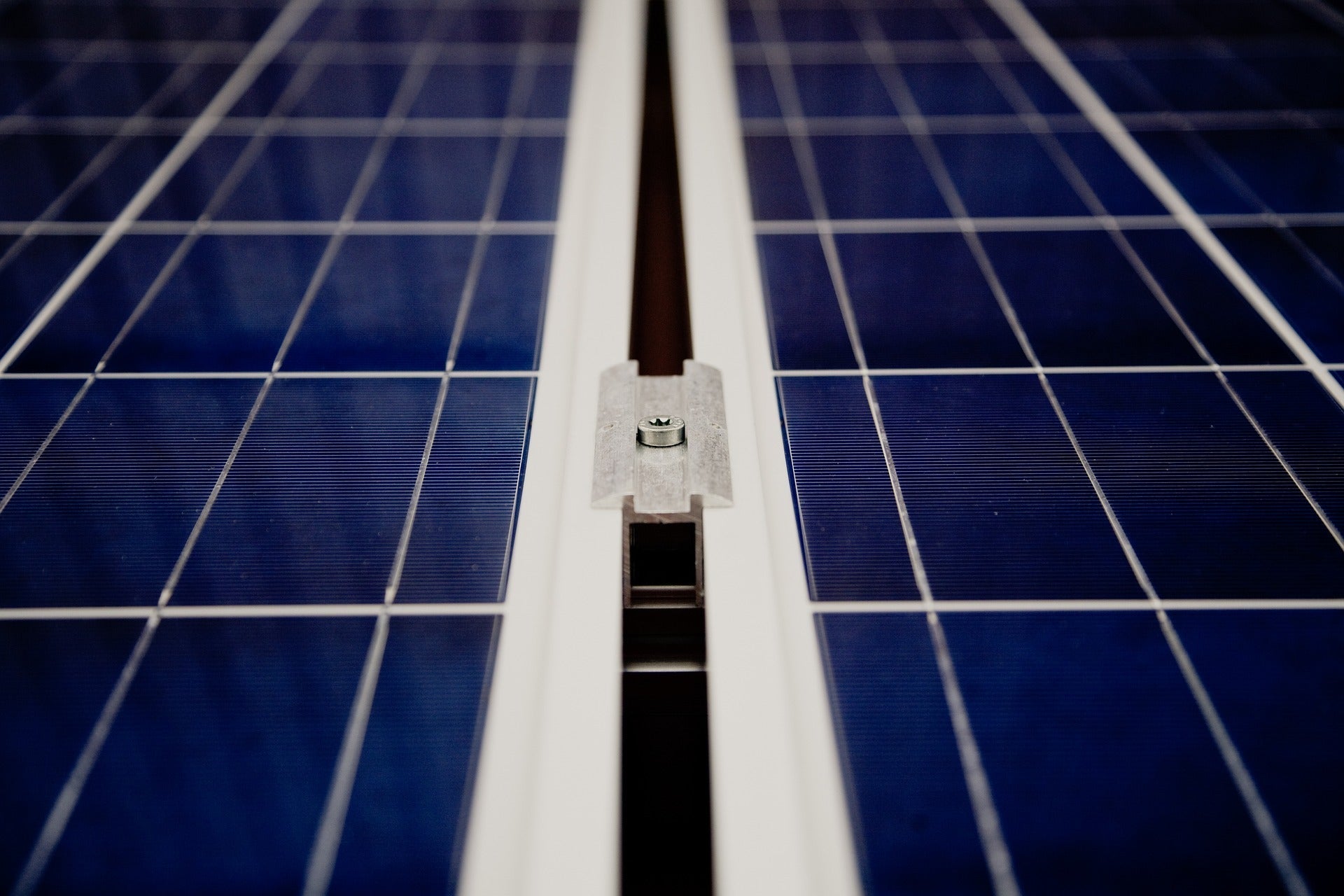

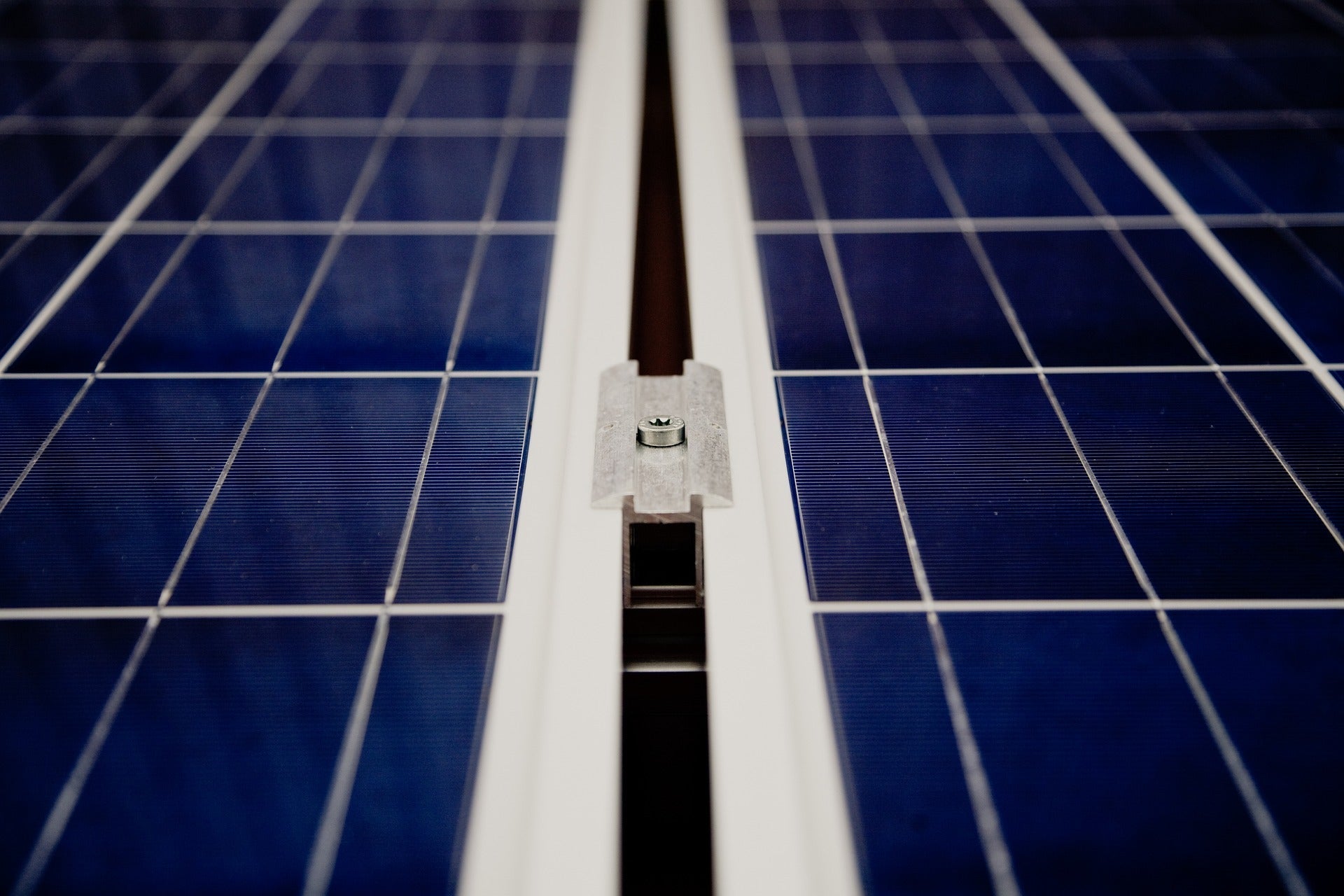

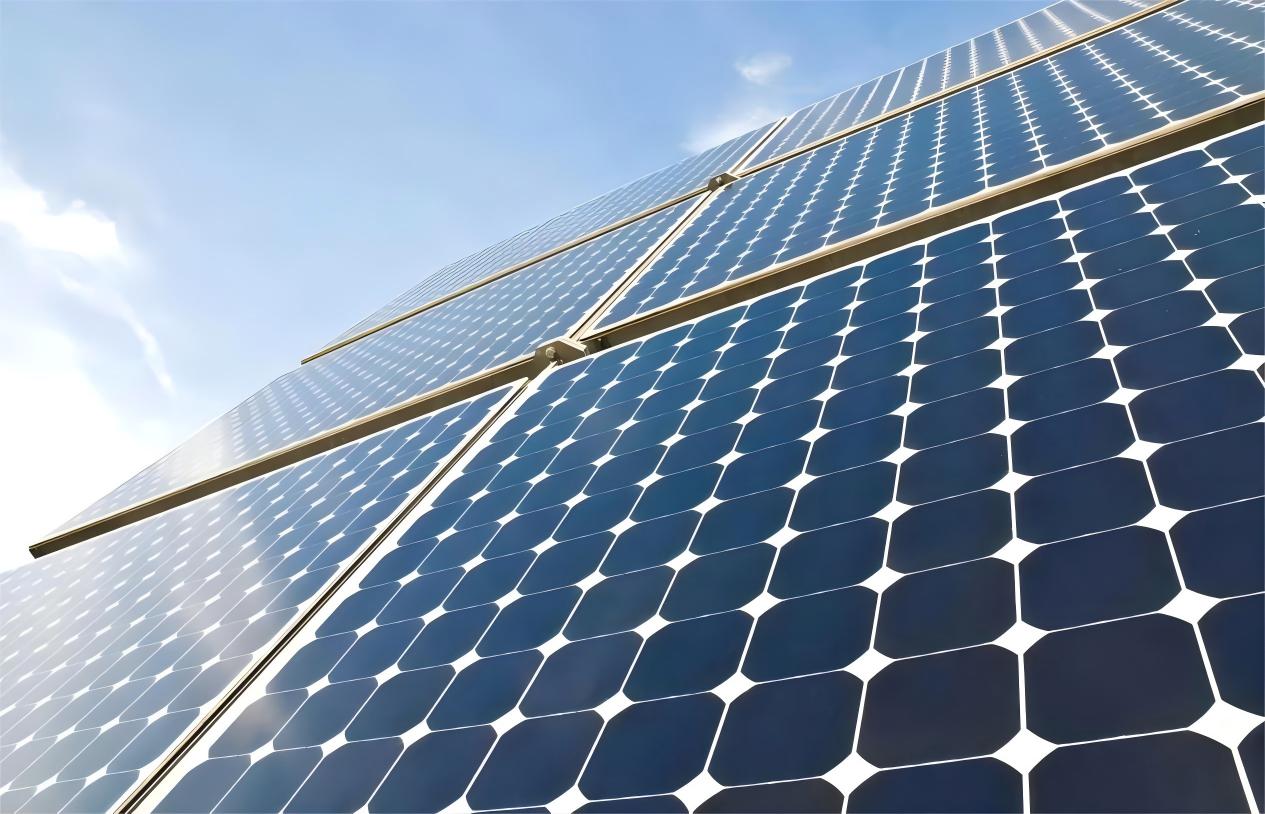

Photovoltaic Glass: This is primarily used as a cover layer for solar panels. Its function is to protect the photovoltaic cells inside the solar panel and provide high light transmittance to maximize the capture of sunlight and convert it into electrical energy.

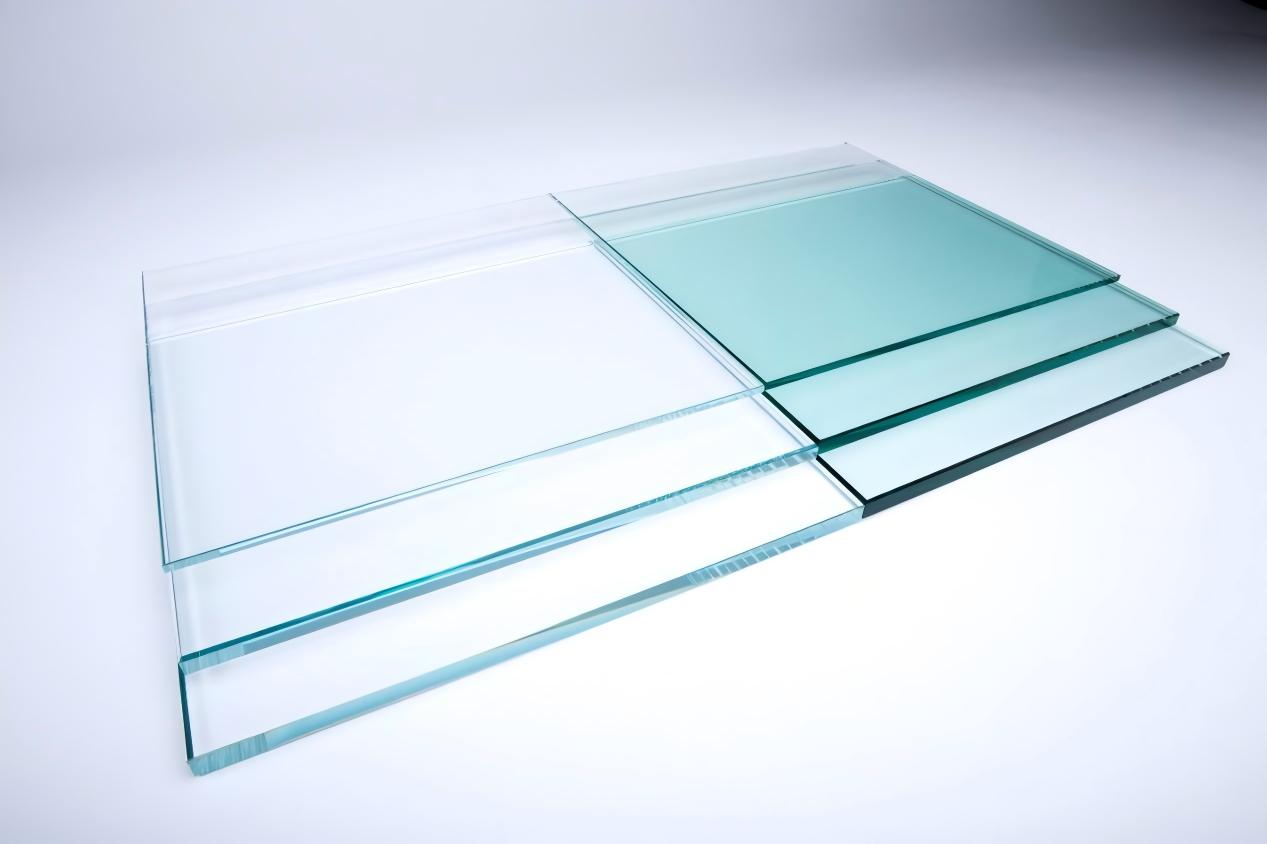

Float Glass: Used in construction and automotive fields, it is commonly used to manufacture windows, walls, mirrors, and other products. It is often utilized as window glass in buildings or mirror glass in furniture, providing light transmittance and visual effects.

2. Manufacturing Processes

Photovoltaic Glass: Producing PV glass usually involves special processes like tempering or special treatment to enhance its durability and compressive strength. The manufacturing process often includes special surface treatments, such as applying anti-reflective and anti-pollution coatings to maximize efficiency.

Float Glass: Float glass is made by melting glass raw materials and pouring them into a float bath, then cooling and processing them into flat glass sheets. This manufacturing method allows the production of large-area glass sheets with uniform thickness, making it relatively cost-effective.

3. Characteristics

Photovoltaic Glass: PV glass typically undergoes special surface treatments to improve its performance in solar panels. For example, anti-reflective coatings can reduce light reflection and increase light absorption, while anti-pollution coatings help keep the glass clean.

Float Glass: Float glass has good light transmittance, flatness, and uniformity, making it suitable for various construction and decorative applications. Its features include high surface smoothness, clear color, and uniform texture.

.

In summary, PV glass is mainly used in solar panels and features special performance and coatings, whereas float glass is a general-purpose glass product with widespread uses and relatively simple manufacturing processes.

Both PV glass and float glass represent outstanding achievements in glass technology. Their distinct applications and characteristics reveal the diversity and possibilities of technology. In the future, these two types of glass will continue to play key roles in their respective fields and will keep evolving and innovating with technological advancements, contributing to the sustainable development of human society. We look forward to the surprises and breakthroughs these two types of glass will bring in the future. If you have any needs or questions regarding PV glass and float glass, please contact us! At New Way Glass, you can obtain high-quality glass at competitive prices!

We will provide you with the highest quality glass solutions.

What Is Tempered Borosilicate Glass to DIN 7080 and Where Is It Primarily Used?

DIN 7080 tempered borosilicate glass combines exceptional strength, thermal stability, and chemical resistance. Widely used in reactors, sight glasses, and lab equipment, it ensures safety and clarity under extreme conditions.

Unveiling the "King of Glass": How Tempered Borosilicate Glass is Reshaping Our Daily Lives

Tempered borosilicate glass—nicknamed the “King of Glass”—combines high strength, thermal stability, and chemical resistance, making it ideal for daily use, laboratory gear, optical components, and more.

Customized ITO/FTO Conductive Glass in Scientific Research Experiments

Customized ITO / FTO conductive glass plays a crucial role in scientific experiments, offering excellent conductivity, transparency, and stability. Ideal for photovoltaics, sensors, and analytical instruments.

How to Quickly Differentiate Between AG, AR, and AF in the Glass Industry

Ultra-thin Rolled Photovoltaic Glass