Glass AR/AG/AF/ITO Coating

Glass AR/AG/AF/ITO coating refers to a range of specialized coatings applied to glass surfaces to enhance their functionality and performance.

> AR (Anti-Reflective) coating reduces glare and reflections, improving visibility and clarity, particularly in high-light environments.

> AG (Anti-Glare) coating minimizes glare and reflections, making the glass more suitable for use in environments with bright lighting or sunlight.

> AF (Anti-Fingerprint) coating repels fingerprints and smudges, keeping the glass surface clean and smudge-free.

> ITO (Indium Tin Oxide) coating is a transparent conductive coating used in electronic devices to create touchscreens or defogging windows.

Overall, these coatings serve to improve the usability, durability, and aesthetics of glass surfaces across various applications.

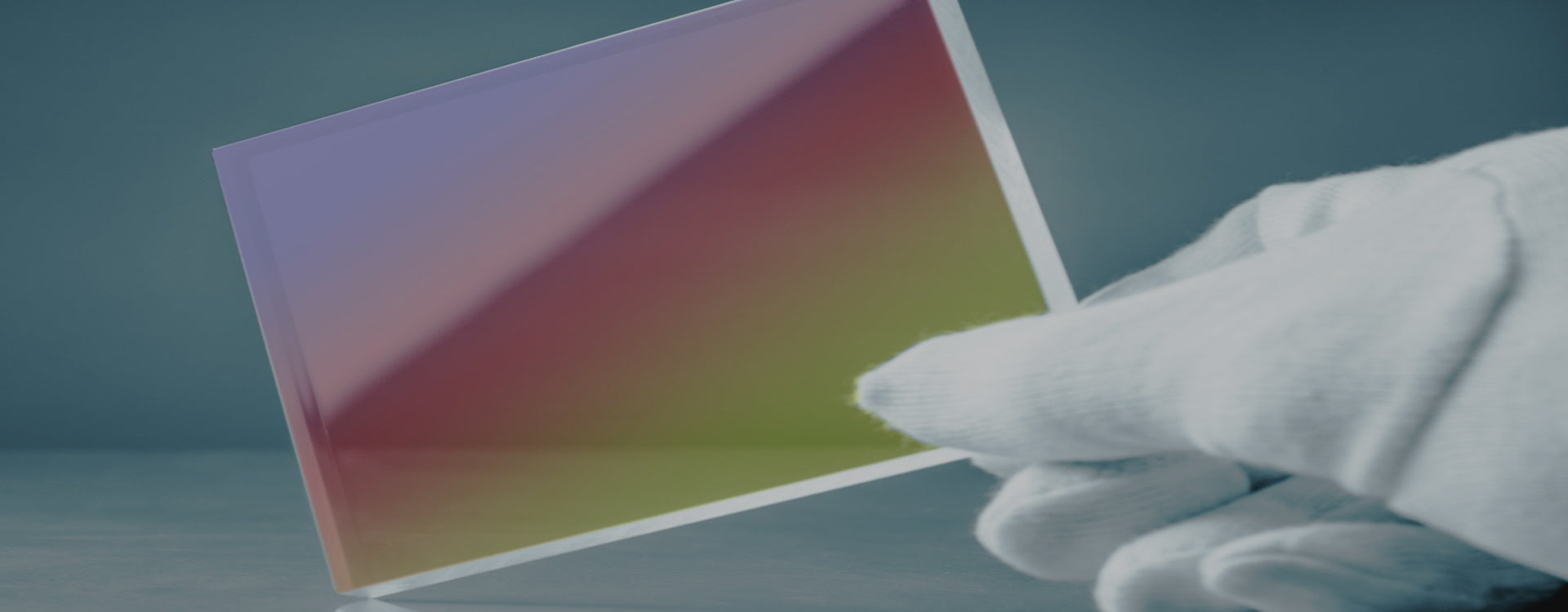

Anti-Reflection Coating

Glass Anti-Reflection Coating minimizes glare and reflections on glass surfaces, enhancing visibility by scattering light. It's widely used in optical devices like eyeglasses and camera lenses to reduce eyestrain and improve clarity.

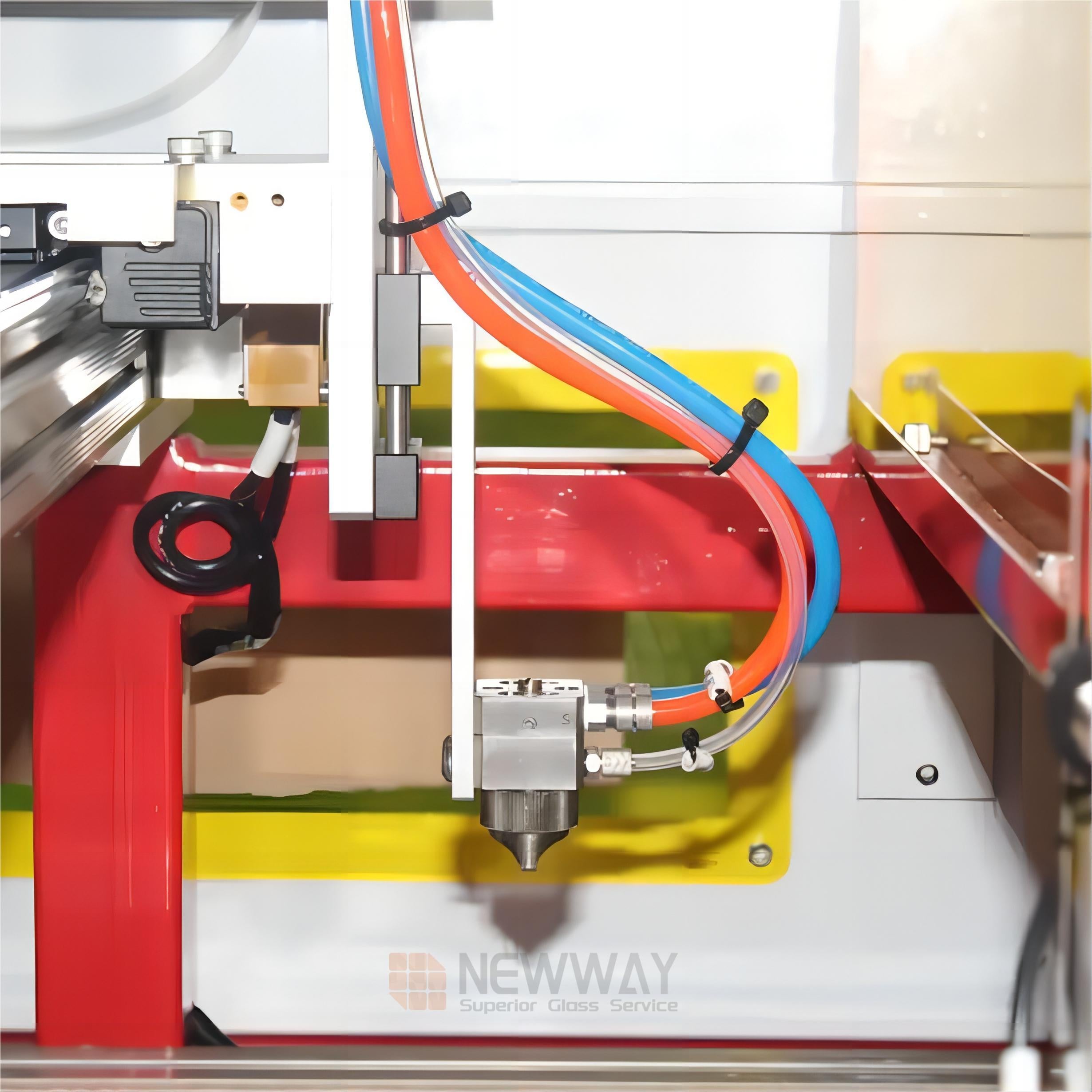

Anti-Glare Coating

Applying Glass Anti-Glare Coating involves cleaning the glass, depositing a specialized anti-glare material, curing the coating, and conducting quality control checks. This process aims to reduce reflections and enhance visibility on glass surfaces.

Anti-Fingerprint Coating

Glass Anti-Fingerprint Coating is a treatment applied to glass surfaces to repel fingerprints and smudges, keeping the glass clean and easy to maintain. This coating creates a hydrophobic and oleophobic layer, preventing oils and residues from sticking. It's commonly used in electronic devices, displays, and architectural glass for improved aesthetics and user experience.

ITO (Indium Tin Oxide) Coating

The process of applying Glass ITO (Indium Tin Oxide) Coating involves cleaning the glass surface, depositing a thin layer of ITO using techniques like sputtering or vapor deposition, curing the coating for durability, and conducting quality checks. This creates a transparent and conductive surface suitable for electronic devices such as touchscreens and displays.

Anti-Microbial Coating

The process of applying Glass Anti-Microbial Coating involves cleaning the glass surface, applying a specialized anti-microbial solution or coating, curing it for adhesion and effectiveness, and conducting quality checks. This creates a germ-resistant surface suitable for environments where cleanliness is crucial, such as hospitals and public spaces.