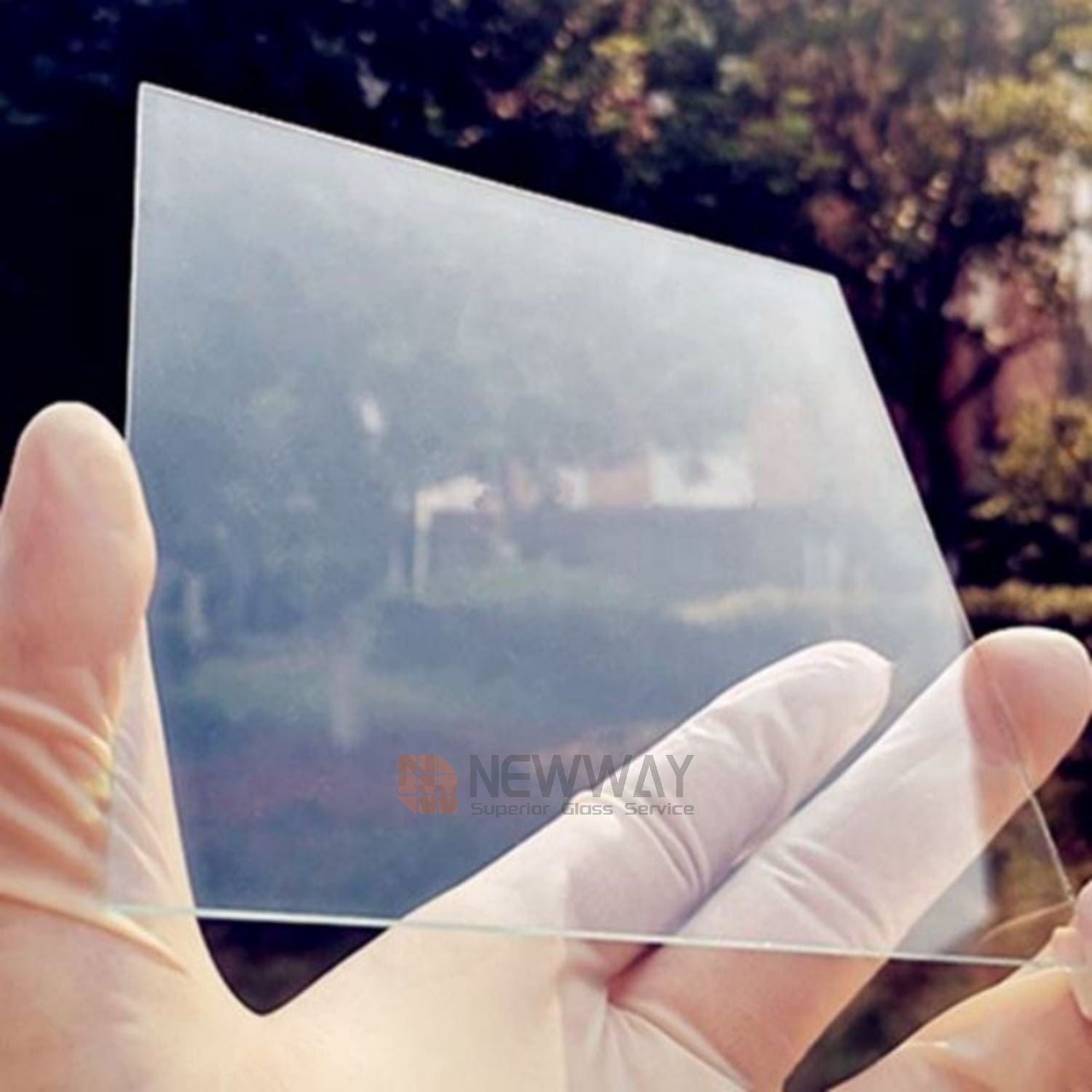

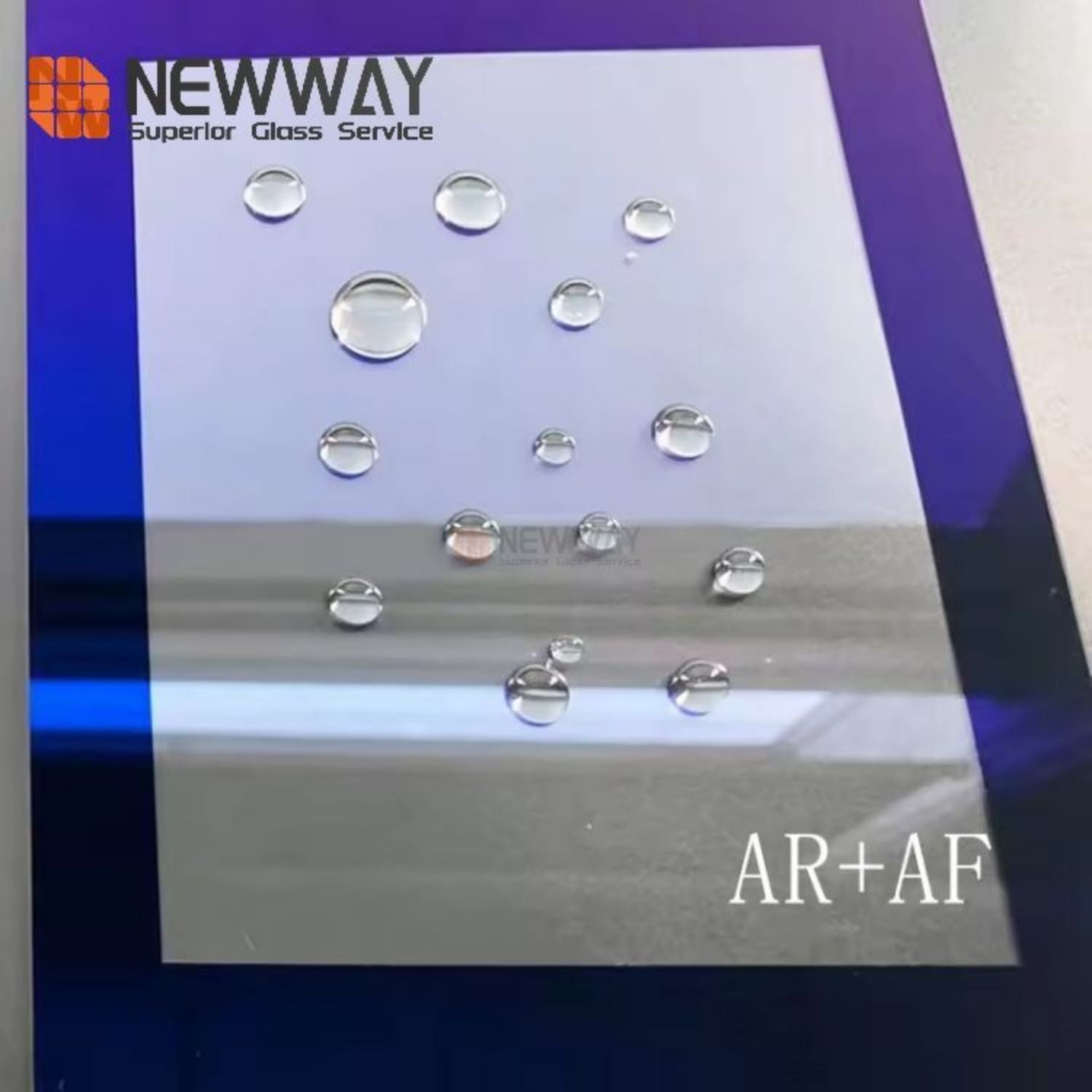

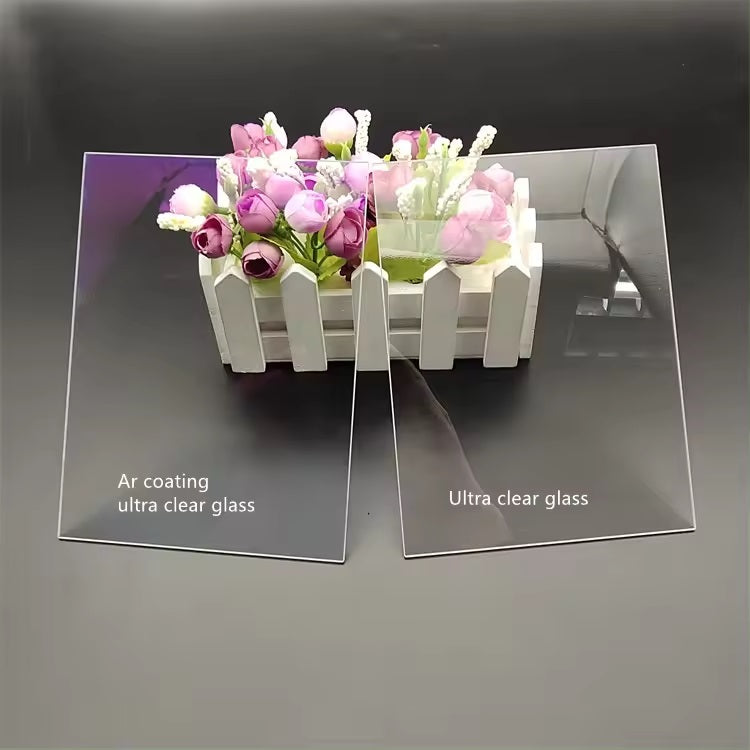

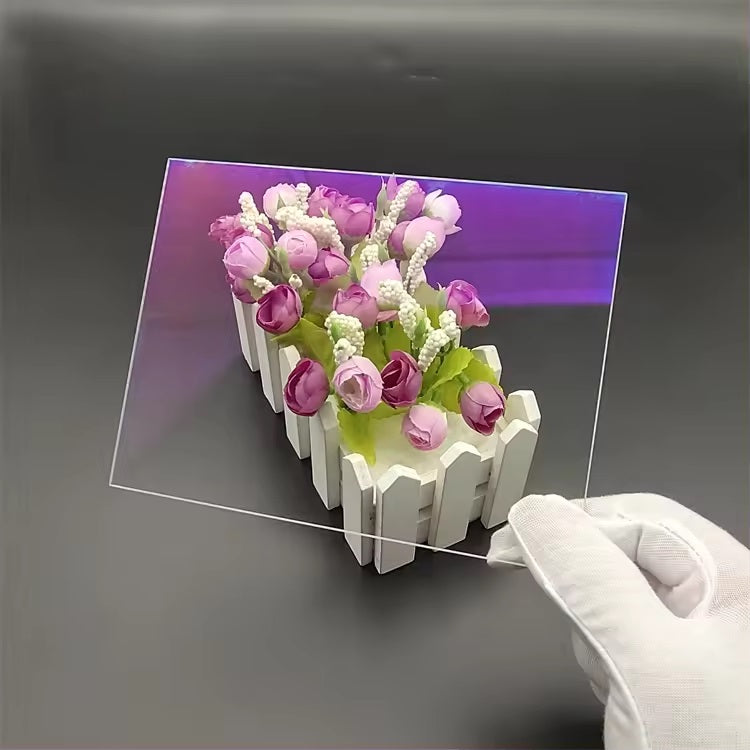

Anti-Reflection Coating

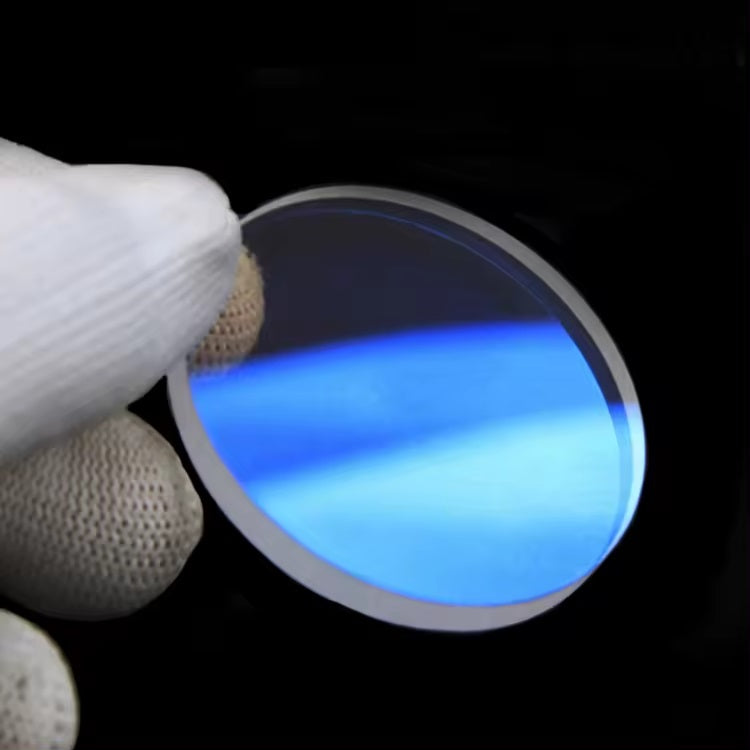

Anti-Reflection Coating is thin films applied to the surface of optical components, such as lenses and glass, to reduce unwanted reflections and glare.

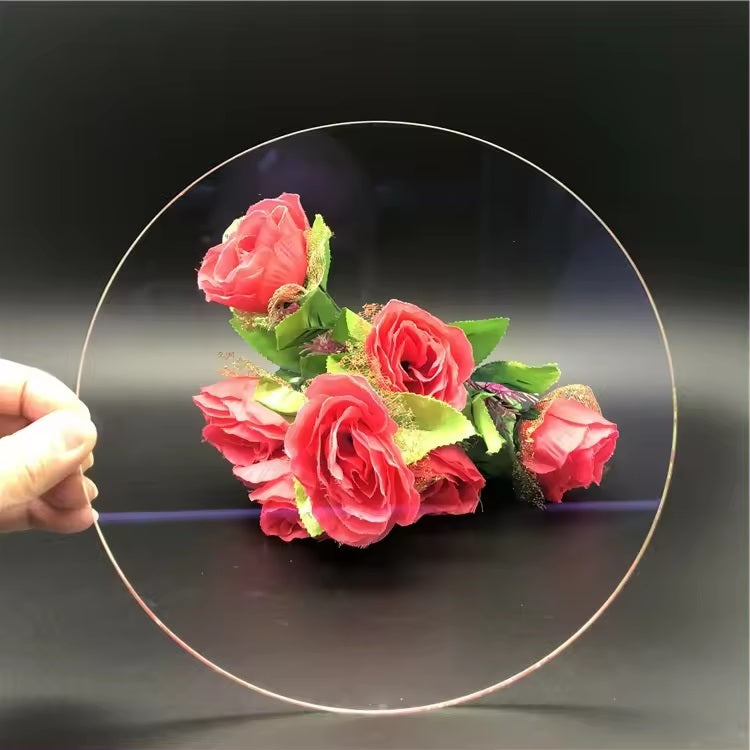

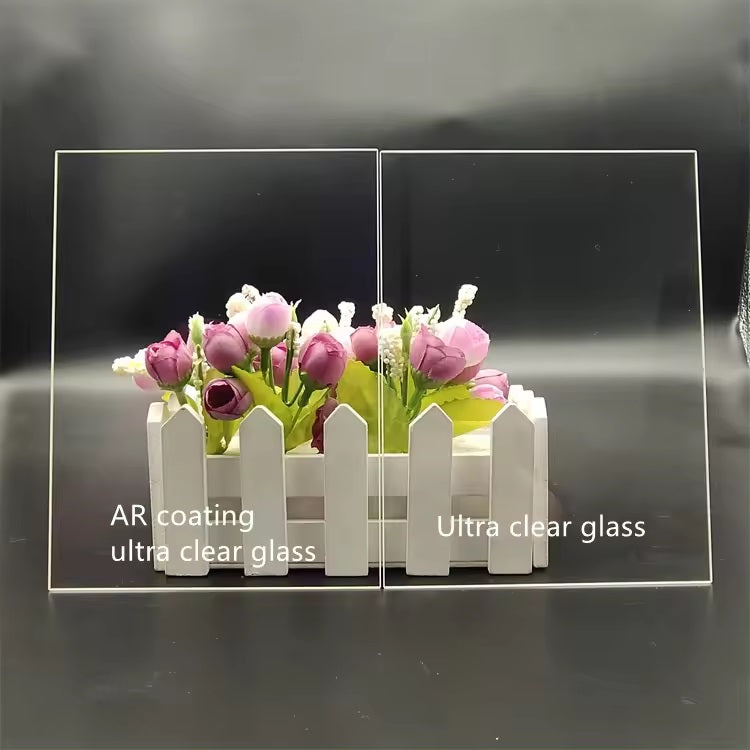

The primary purpose of anti-reflection coatings is to enhance the transmission of light through the optical system by minimizing reflection losses.

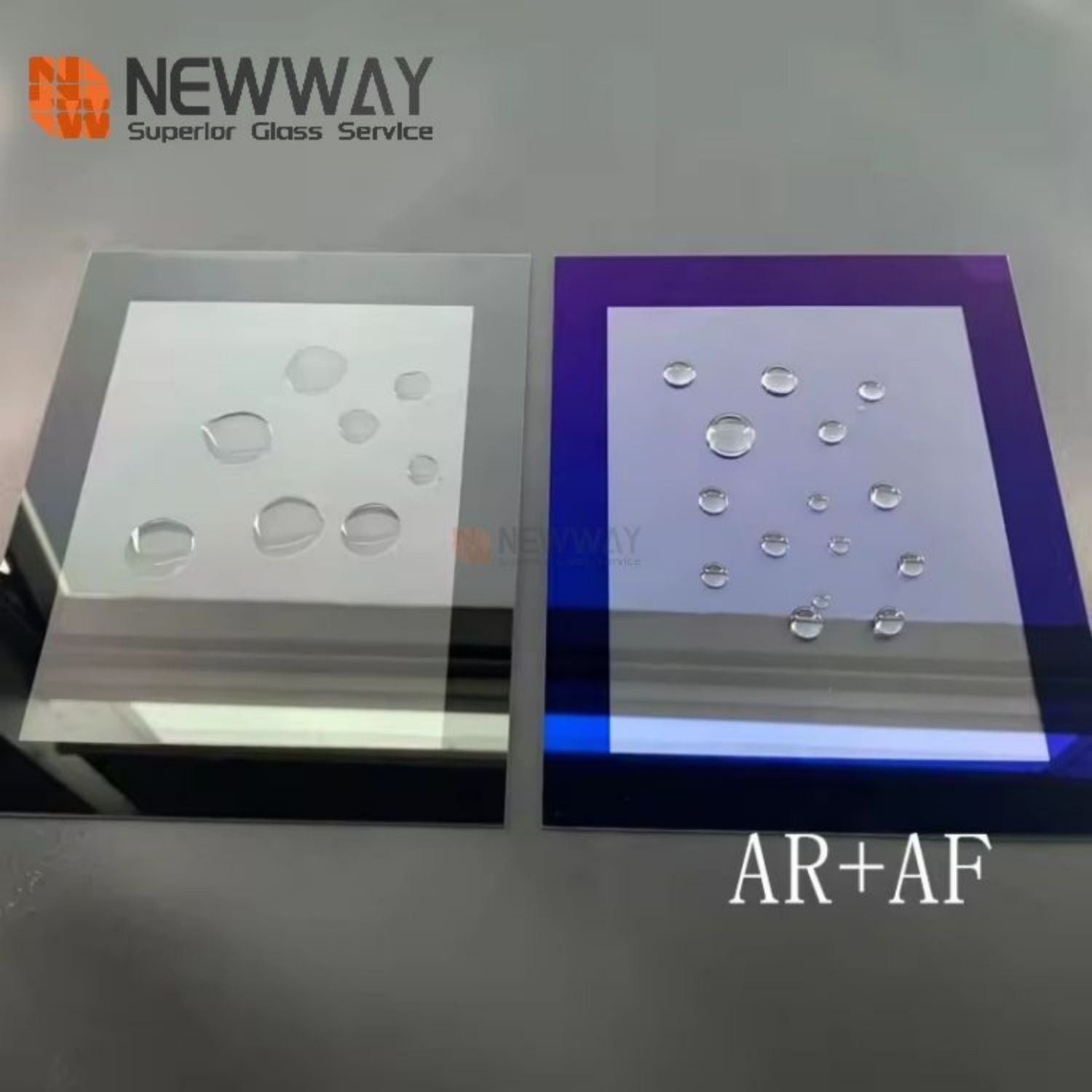

With double-sides AR Coating, the transmittance of the glass can reach 99%, and the reflective rate is under 1%. NWG has both Vacuum Deposition and Sputtering ARC processing methods.

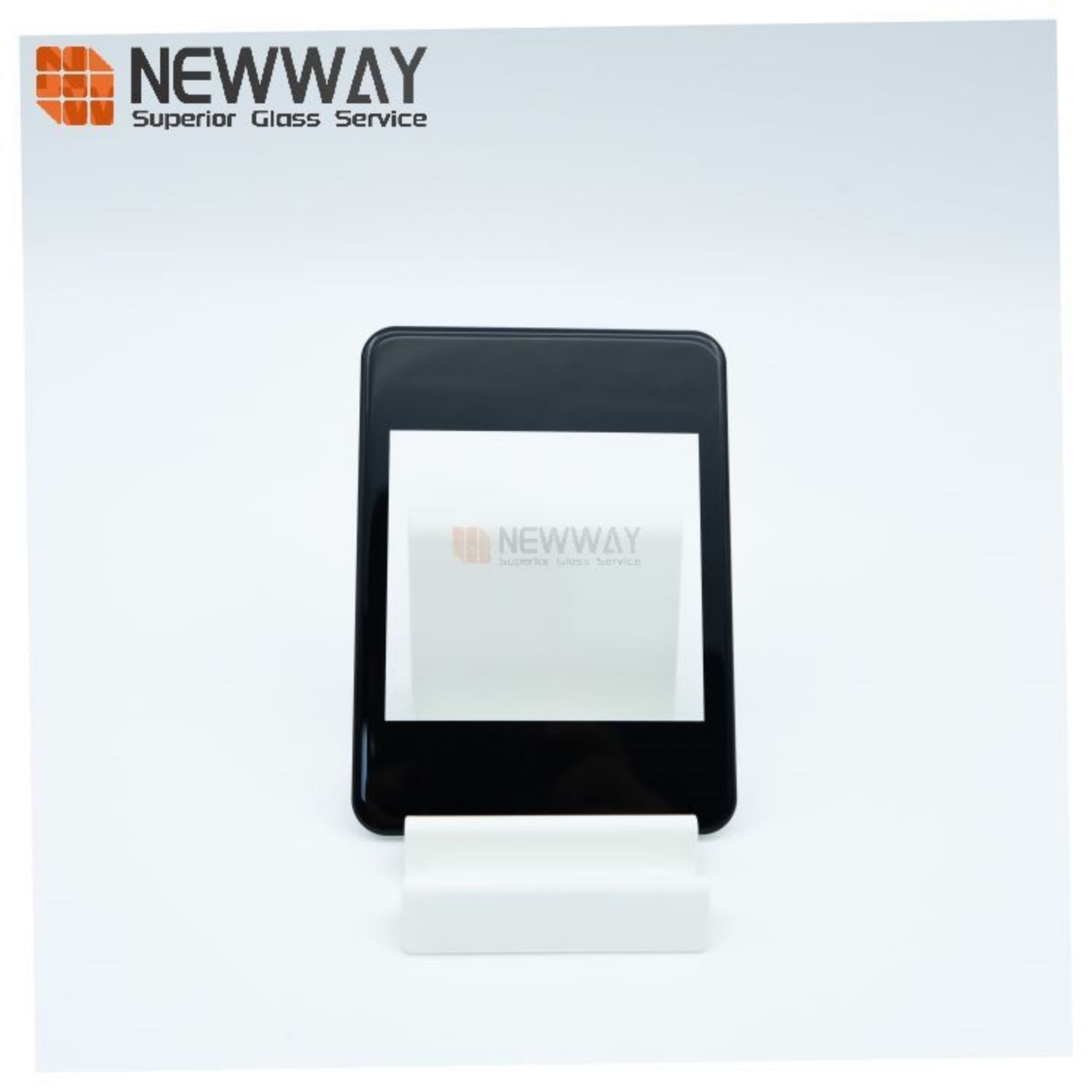

Applications

Solar panels, Electronic devices, Lighting, Laboratory instruments, Automotive Industry, Medical, Artworks and sculptures, etc

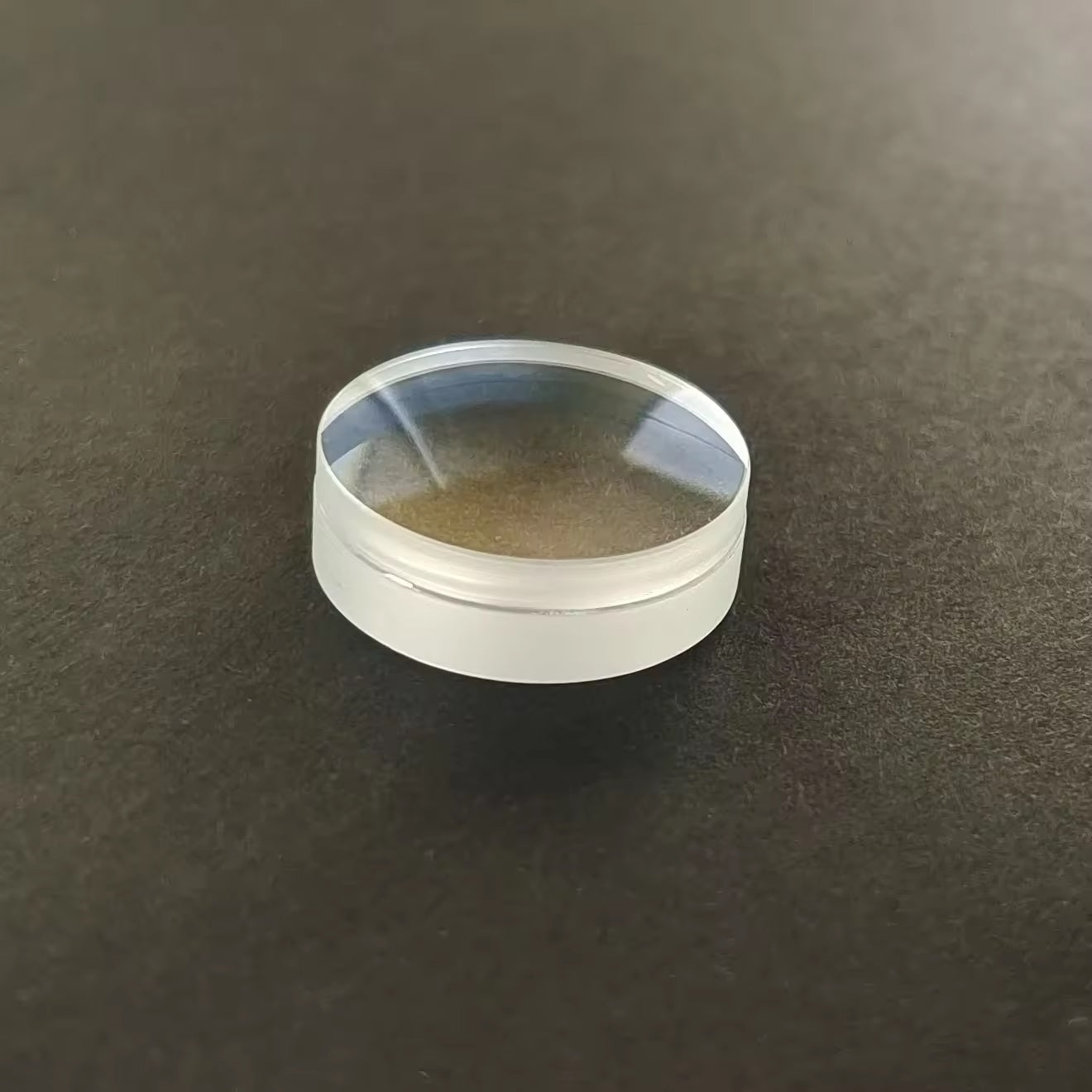

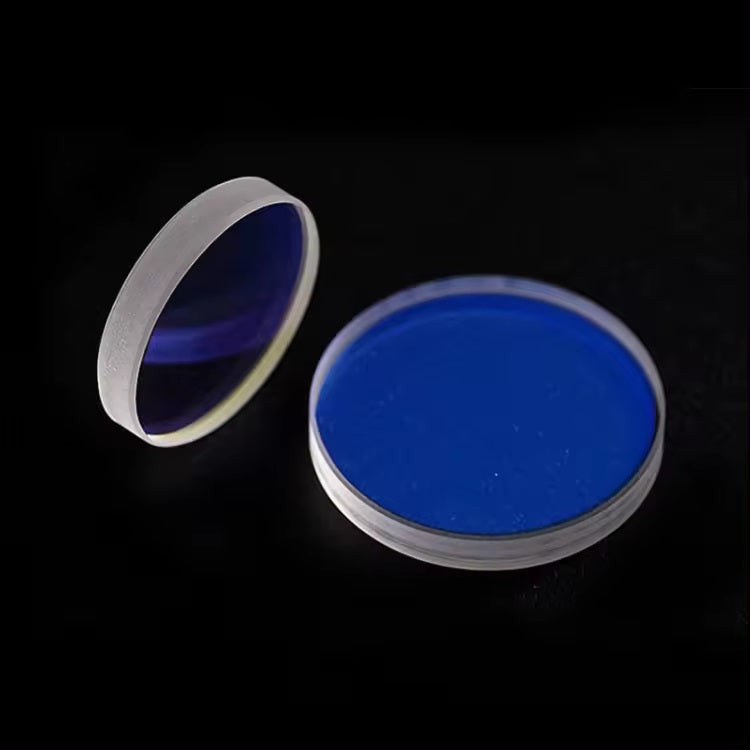

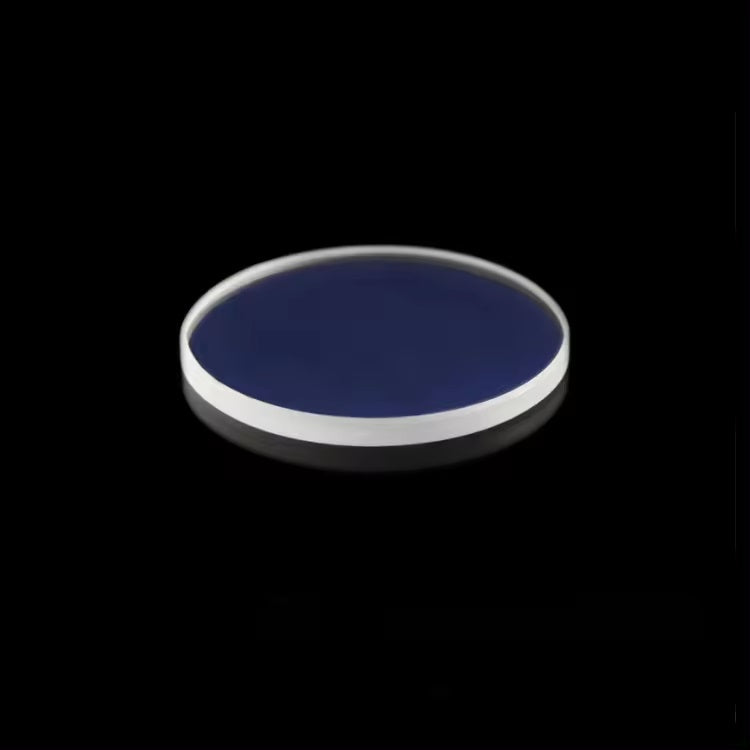

Vacuum Deposition

Vacuum Deposition is the most widely used ARC method. Coating materials, often use metal oxides, are evaporated within a vacuum chamber and deposited onto the optical component's surface.

Advantage

Vacuum deposition produces high-quality films and can achieve uniform coverage on complex shapes and surfaces.