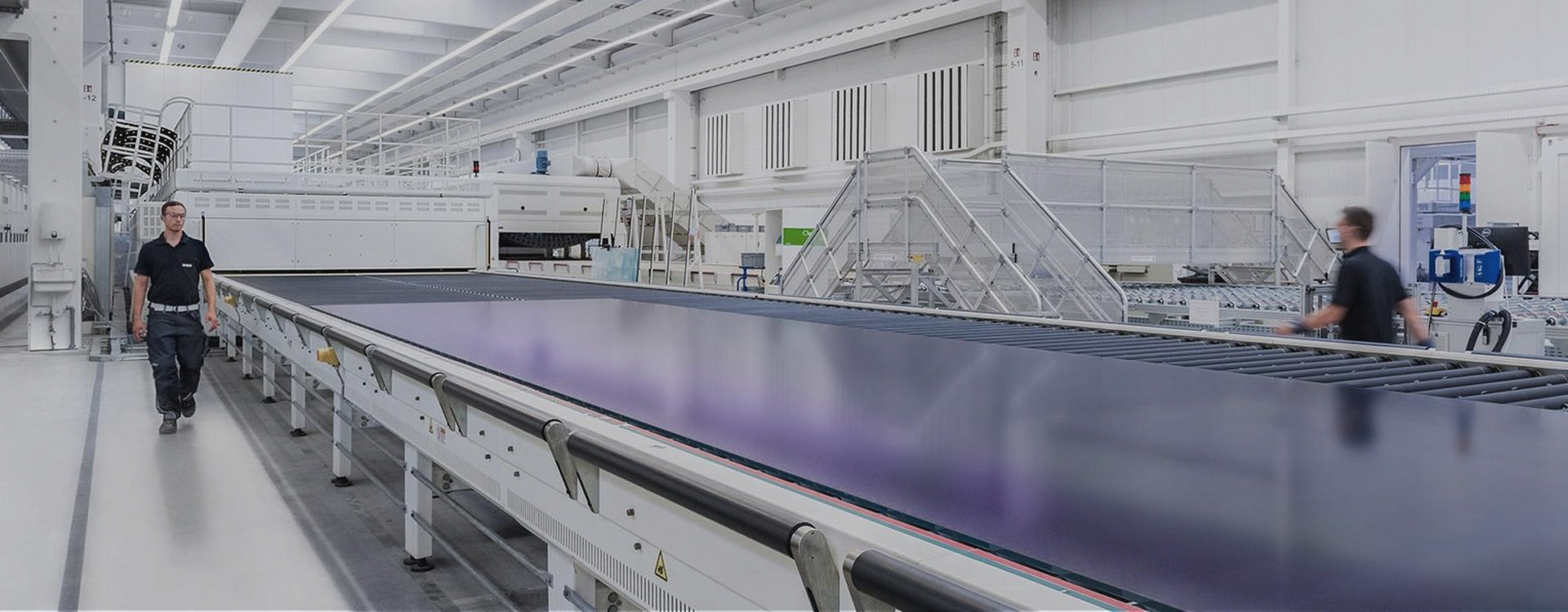

Tempering is a crucial process in glass deep processing that enhances its strength and safety. Physical tempering involves heating the glass to a high temperature and then rapidly cooling it, while chemical tempering strengthens the glass by exchanging ions in a chemical solution.

1.Process

Heating the glass to a high temperature and then rapidly cooling it using forced air or other methods. The rapid cooling creates a strong, balanced internal structure in the glass, making it tougher and more resistant to impact.

2.Strength Enhancement

The strength of physical tempered glass is approximately 4-5 times greater than that of untreated glass of the same thickness.

Tempered glass is resistant to impact and exhibits a characteristic of shattering into small, relatively harmless fragments when broken.

3.Surface Quality

Tempered glass has a smooth and flat surface. However, physical tempering can introduce some minor distortions or visual anomalies.

4.Flexibility

Physical tempered glass is rigid and cannot be further processed or cut after the tempering process.

Any attempts to modify physical tempered glass after tempering will result in the glass shattering into small, safer fragments.

5.Size Range

25x25mm — 2440x1600mm

6.Thickness Range

1.8mm—20mm (Thickness less than 3mm can be only half physical tempered)

1.Process

The glass is immersed in a bath of molten salt or potassium nitrate. The ions in the salt or potassium nitrate replace the smaller sodium ions in the glass surface, creating a compressive stress layer that enhances strength.

2.Strength Enhancement (CS/DOL)

Soda-lime Glass: CS:400-720Mpa, DOL:5-10μm

Mid-Aluminum Glass: CS:600-750Mpa, DOL:9-12μm

High-Aluminum Glass: CS:700-950Mpa, DOL:35-50μm

3.Surface Quality

Chemically strengthened glass retains a smoother surface with minimal distortions, providing improved optical quality compared to tempered glass.

4.Flexibility

Chemically strengthened glass is more flexible than tempered glass. It can be further processed, cut, or drilled after the strengthening process. When broken, it still shatters in long pointed splinters similar to float glass.

5.Internal Size

2400mm(L)x1600mm(W)x1800mm(H)

6.Applications

Electronic devices

Solar panels

Lighting

Laboratory instruments

Automotive Industry

Medical

Artworks and sculptures, etc

(Typically for the glass thickness below 3mm)