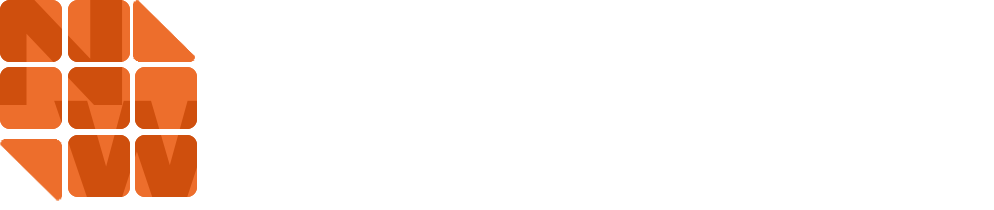

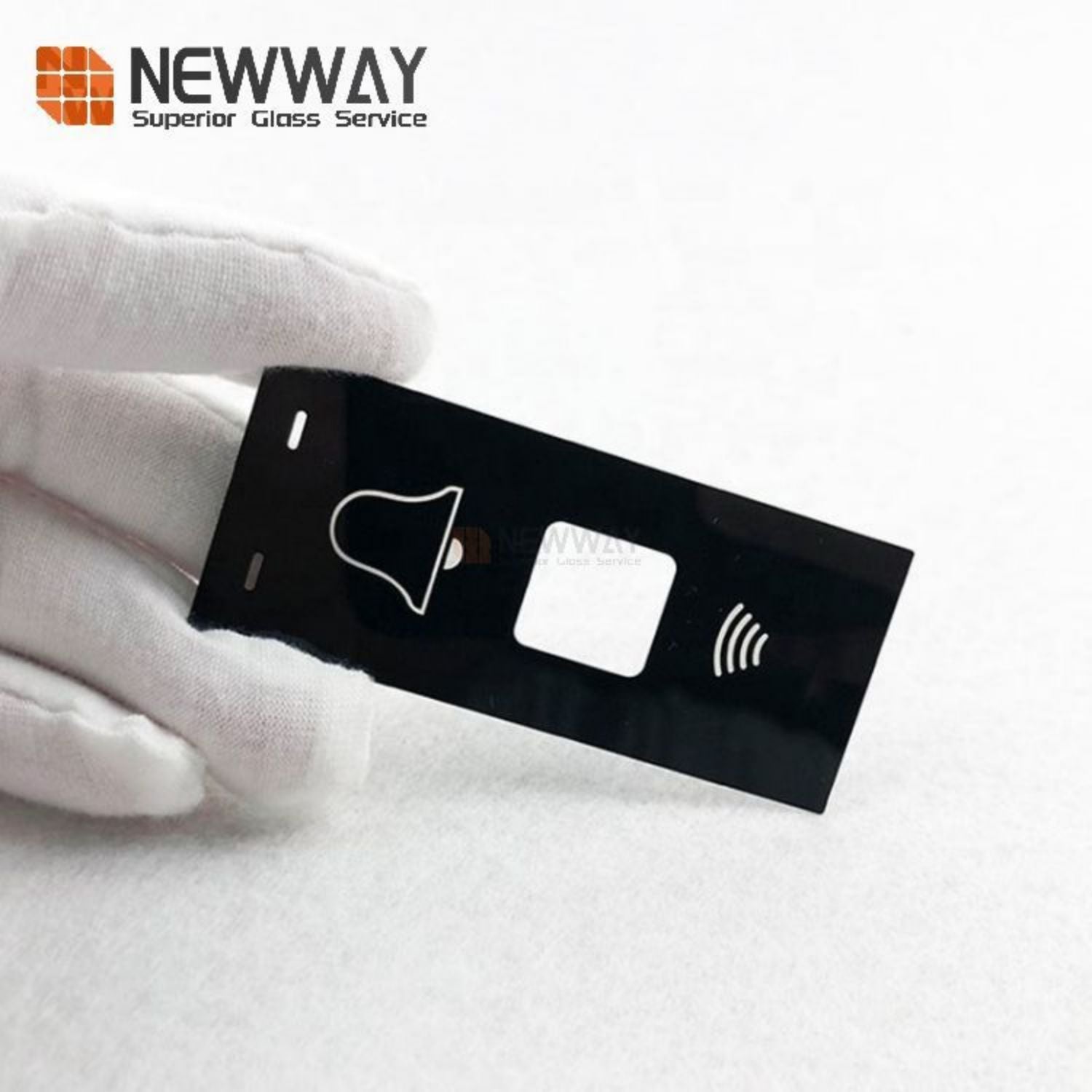

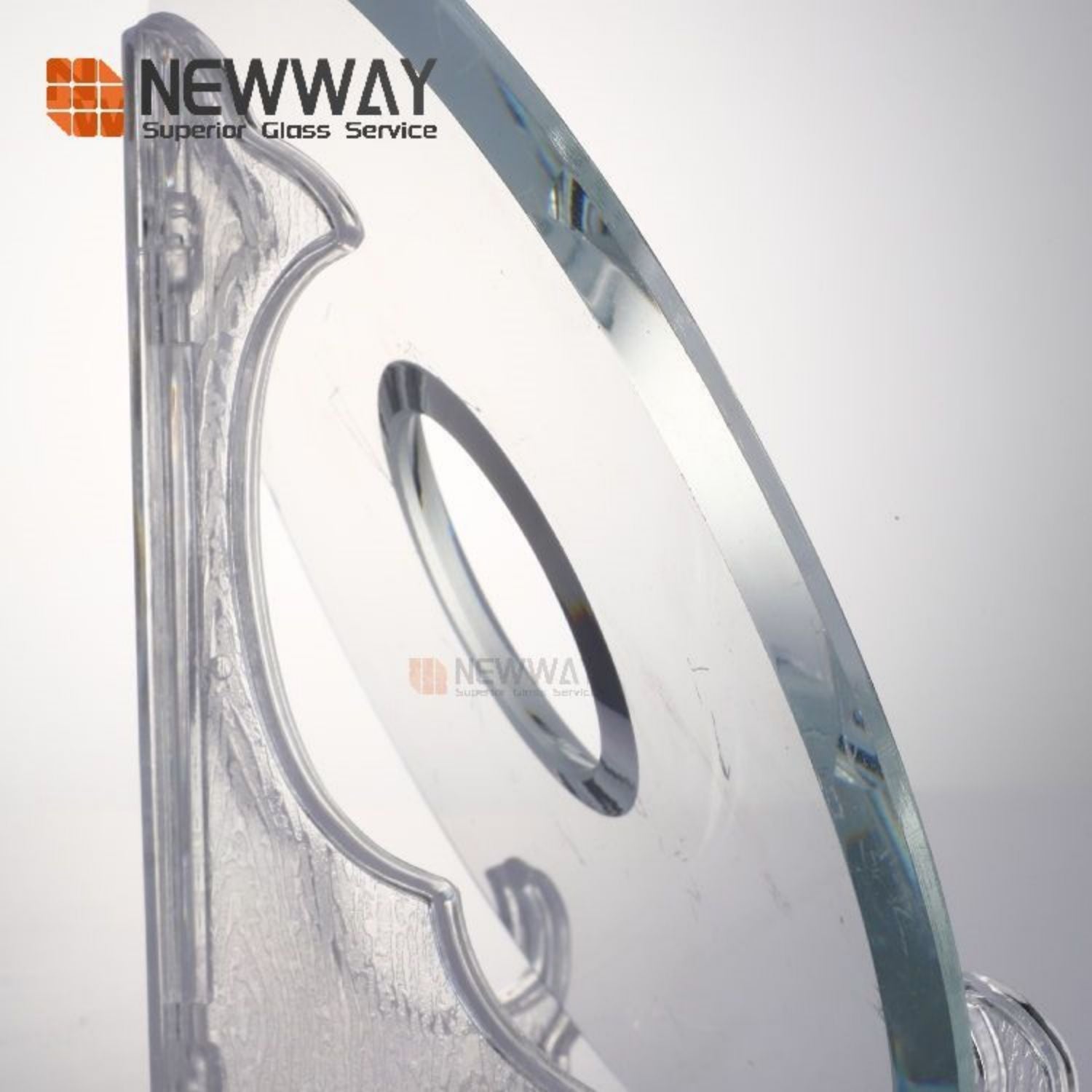

Precise Glass Drilling

Precise glass drilling is essential in various industries, such as electronics, optics, medical devices, and automotive.Glass drilling is typically performed before the glass undergoes physical tempering or chemical strengthening. This procedure allows for a wide range of applications across industries, from assembly to art and design.

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

Three Different Drilling Methods Offered

Drilling Machine:

Process:

Traditional drilling machines equipped with specialized glass drill bits are commonly used for drilling holes in glass. The drill bit must be designed for glass to prevent cracking and chipping.

Advantages:

Simple and cost-effective for basic drilling tasks.

Suitable for small-scale operations.

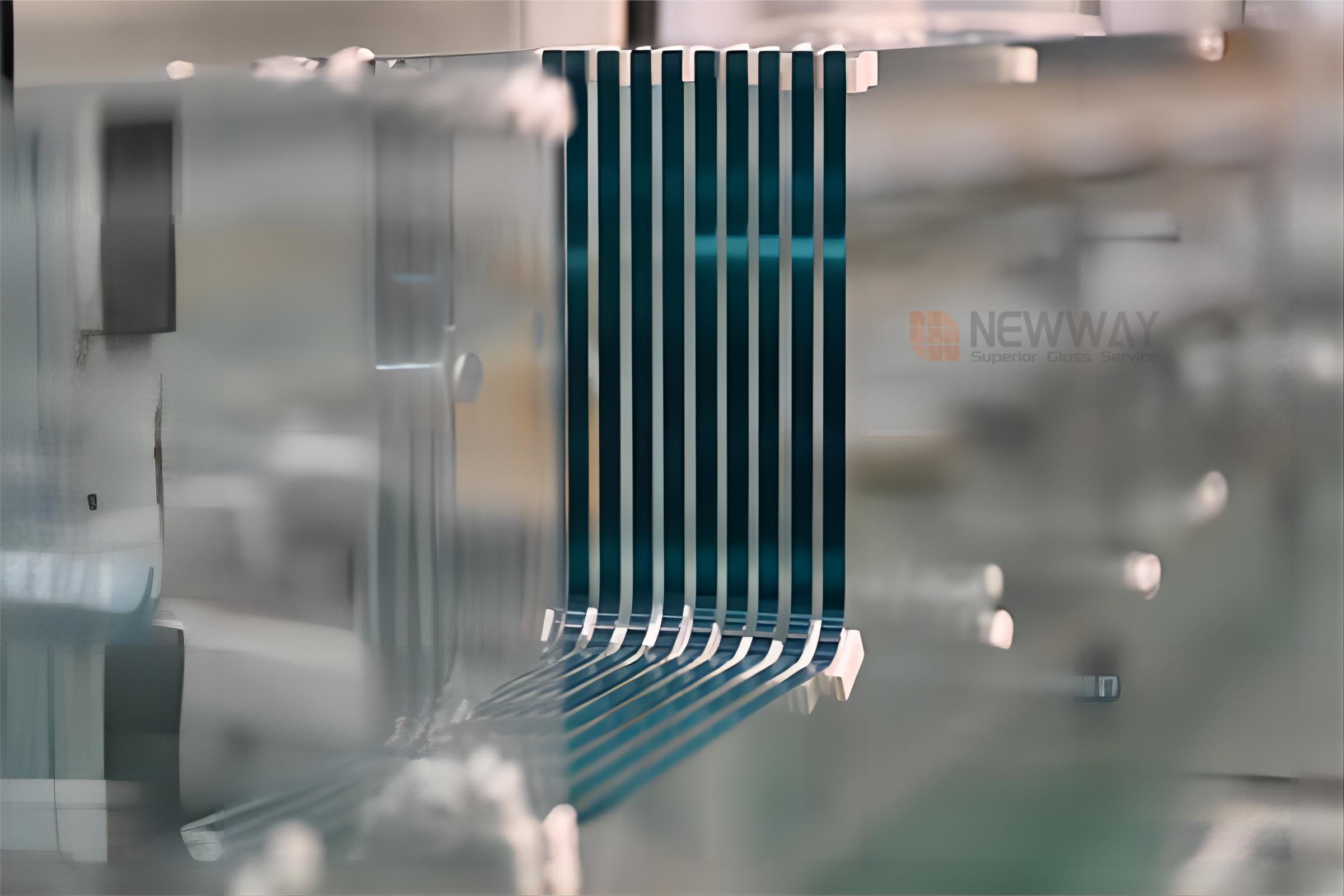

CNC Machine:

Process:

Computer Numerical Control (CNC) machines can be programmed to drill precise holes in glass. The CNC system controls the movement of the drill bit with high accuracy.

Advantages:

Offers precise and automated drilling.

Ideal for intricate designs and large-scale production.

Can handle various hole sizes and shapes.

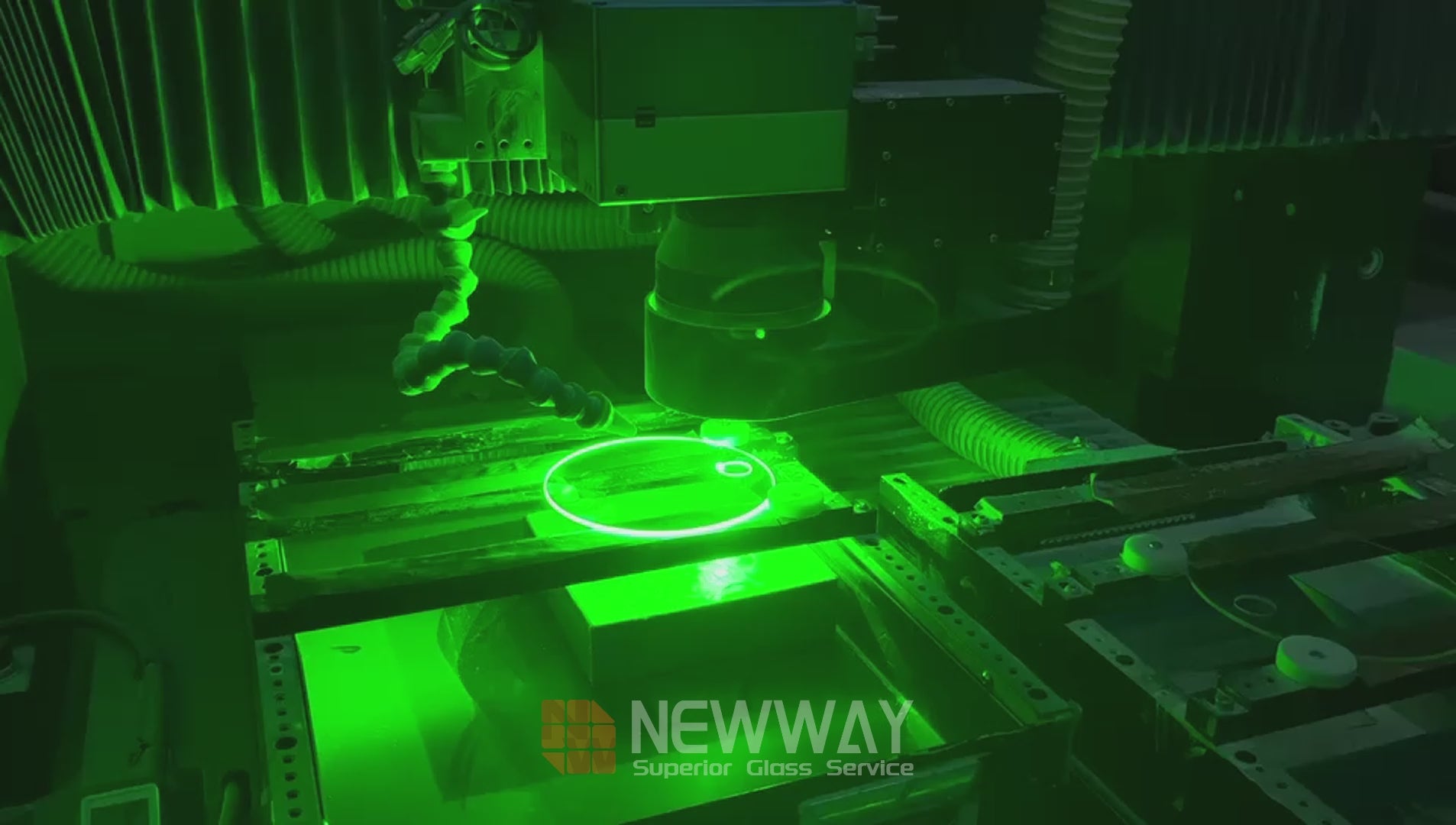

Laser Machine

Process:

Laser machines use focused laser beams to cut or drill through glass. The laser creates heat, which melts or vaporizes the glass at the desired drilling points.

Advantages:

Super high precision(Accurate to 0.01mm), clean edges.

Suitable for delicate or complex designs.

Non-contact process, and minimal risk of breakage.