Photovoltaic glass is an essential key material for solar photovoltaic power generation modules. Rolled glass is usually chosen for its advantages such as light transmission and weather resistance. The quality of photovoltaic glass directly affects the performance and lifespan of solar photovoltaic power generation modules, playing a crucial role in solar photovoltaic power generation.

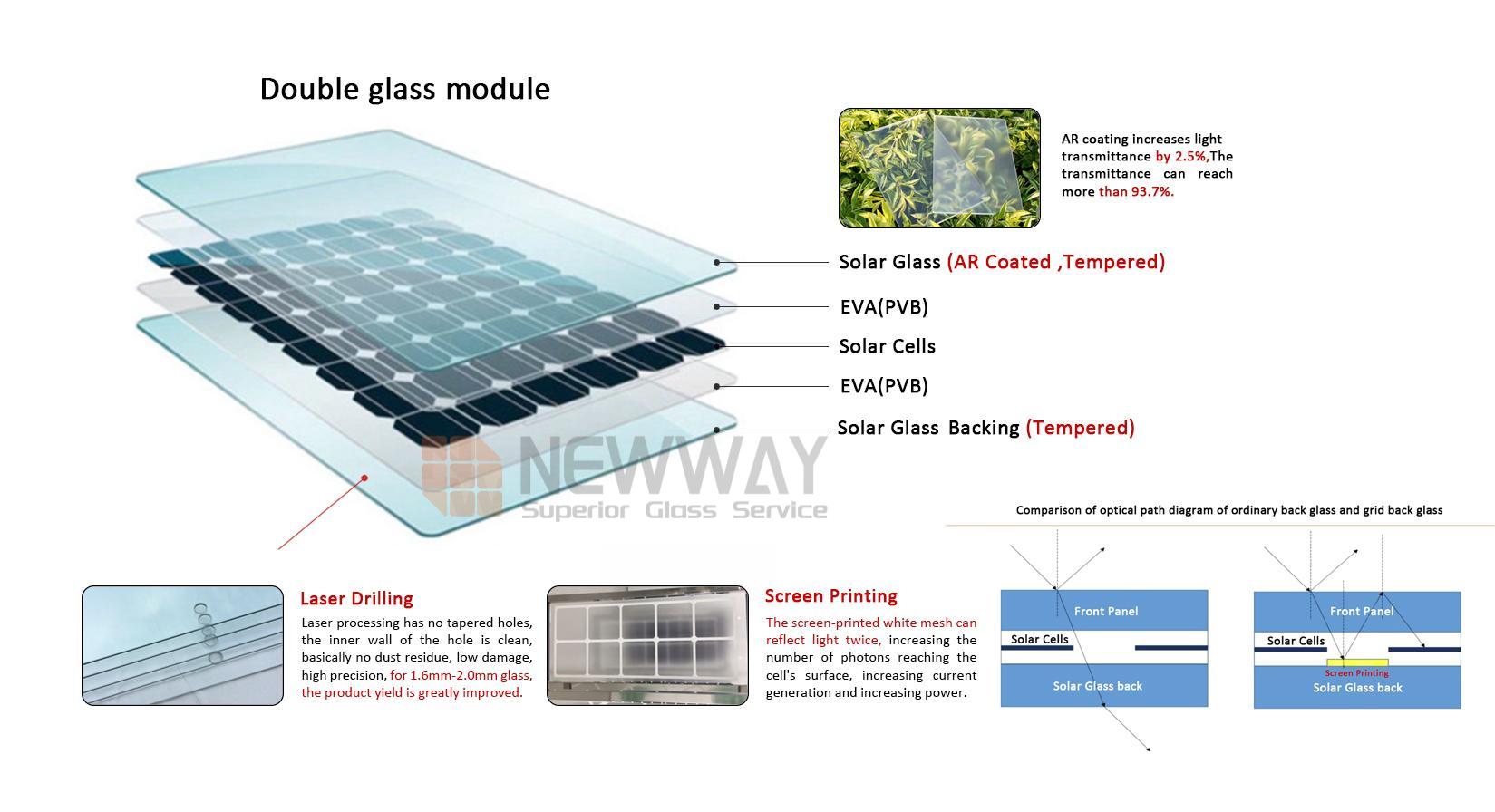

The rapid development and application of Building-integrated photovoltaics (BIPV) have driven solar photovoltaic power generation modules towards lighter and thinner designs, effectively improving installation efficiency and reducing the load on buildings. The thickness of rolled photovoltaic glass has gradually transitioned from 3.2 mm and 2.5 mm to 2.0 mm and below. Especially in double-glass modules used in solar photovoltaic power generation, their high power generation efficiency, long lifespan, and ease of building integration have been recognized by the market.

According to the China Photovoltaic Industry Association, the penetration rate of double-glass modules is expected to reach 60% by 2025, becoming the mainstream product in the solar photovoltaic power generation module market, significantly increasing the demand for rolled glass, especially ultra-thin rolled glass.

The development of thinner rolled photovoltaic glass poses many challenges in production. To improve the quality of ultra-thin rolled glass, new materials and technologies are rapidly being applied. New Way Glass will explore the technological solutions related to the ultra-thin rolled photovoltaic glass production line.

New Technologies in Ultra-thin Rolled Photovoltaic Glass Projects

The strength and transmittance of rolled photovoltaic glass determine the lifespan and power generation efficiency of photovoltaic modules. Glass transmittance can be achieved by controlling the iron oxide content in the raw materials. However, as the thickness of the rolled glass decreases, the strength of the glass also declines rapidly, seriously affecting the lifespan of photovoltaic modules. Typically, manufacturers increase the aluminum oxide content in soda-lime-silicate glass components to improve strength, but this increases the viscosity of the glass melt, making it more difficult to melt and clarify. Additionally, reducing the thickness of the glass increases the difficulty of rolling and annealing, requiring technological innovations in each process to improve production efficiency and product quality.

Energy-saving and Environmental Protection Technologies

The glass industry is gradually moving from high energy consumption and high pollution to greener practices, focusing more on sustainable development and environmental protection. The ultra-thin rolled photovoltaic glass project strengthens the improvement and updating of production processes and equipment technologies to reduce energy consumption and exhaust emissions during production, ensuring environmental compliance.

Trends in Ultra-thin Rolled Photovoltaic Glass

1. Improving the Strength of Ultra-thin Rolled Photovoltaic Glass

The complex application environment of solar photovoltaic modules requires ultra-thin rolled glass to maintain high strength. With the increase in the penetration rate of double-glass modules, the demand for ultra-thin rolled glass has risen significantly. However, the insufficient strength of ultra-thin rolled glass limits the thinness of double-glass modules. Research needs to focus on improving the strength of glass through component design and addressing the tempering issues of ultra-thin rolled glass to achieve high strength.

Conclusion

The ultra-thin rolled photovoltaic glass production line project focuses on the application of new technologies in glass melting and clarification, rolling forming, and annealing processes to achieve industrial production of ultra-thin rolled glass, improve product quality, and reduce production costs. The construction of the production line should align with energy conservation, emission reduction, and air pollution control, adopting new equipment and technologies to achieve ultra-low emissions and green production. Enhancing the strength and transmittance of ultra-thin rolled photovoltaic glass to improve glass performance and increase photoelectric conversion efficiency is the main research direction of New Way Glass. If you have any needs or questions about photovoltaic glass, please feel free to consult us. New Way Glass will provide you with competitive wholesale prices and high-quality photovoltaic glass.

We will provide you with the highest quality glass solutions.

What Is Tempered Borosilicate Glass to DIN 7080 and Where Is It Primarily Used?

DIN 7080 tempered borosilicate glass combines exceptional strength, thermal stability, and chemical resistance. Widely used in reactors, sight glasses, and lab equipment, it ensures safety and clarity under extreme conditions.

Unveiling the "King of Glass": How Tempered Borosilicate Glass is Reshaping Our Daily Lives

Tempered borosilicate glass—nicknamed the “King of Glass”—combines high strength, thermal stability, and chemical resistance, making it ideal for daily use, laboratory gear, optical components, and more.

Customized ITO/FTO Conductive Glass in Scientific Research Experiments

Customized ITO / FTO conductive glass plays a crucial role in scientific experiments, offering excellent conductivity, transparency, and stability. Ideal for photovoltaics, sensors, and analytical instruments.

What is the Difference Between Solar Photovoltaic Glass and Float Glass?

Application of ITO Coated Glass in Solar Technology