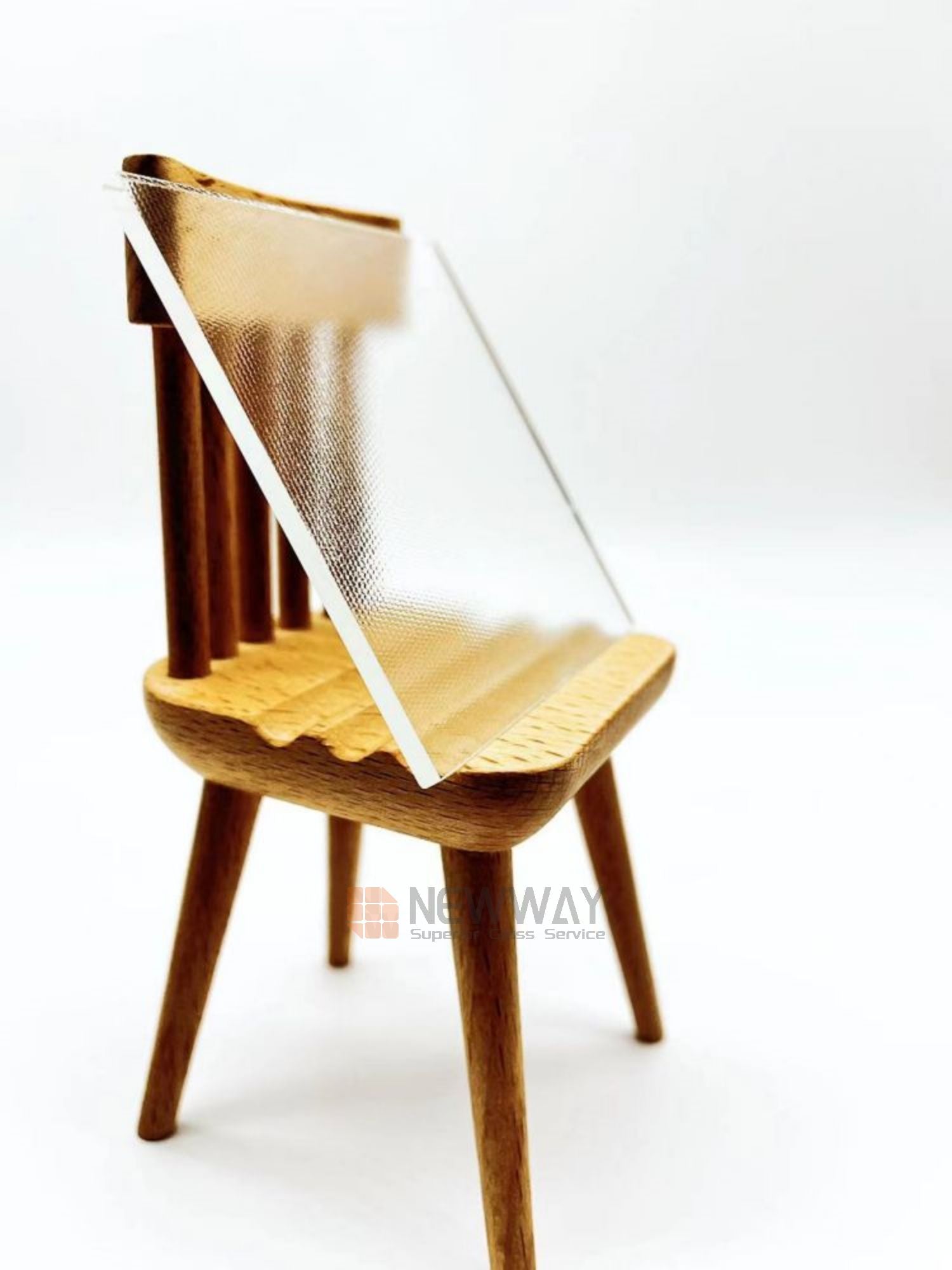

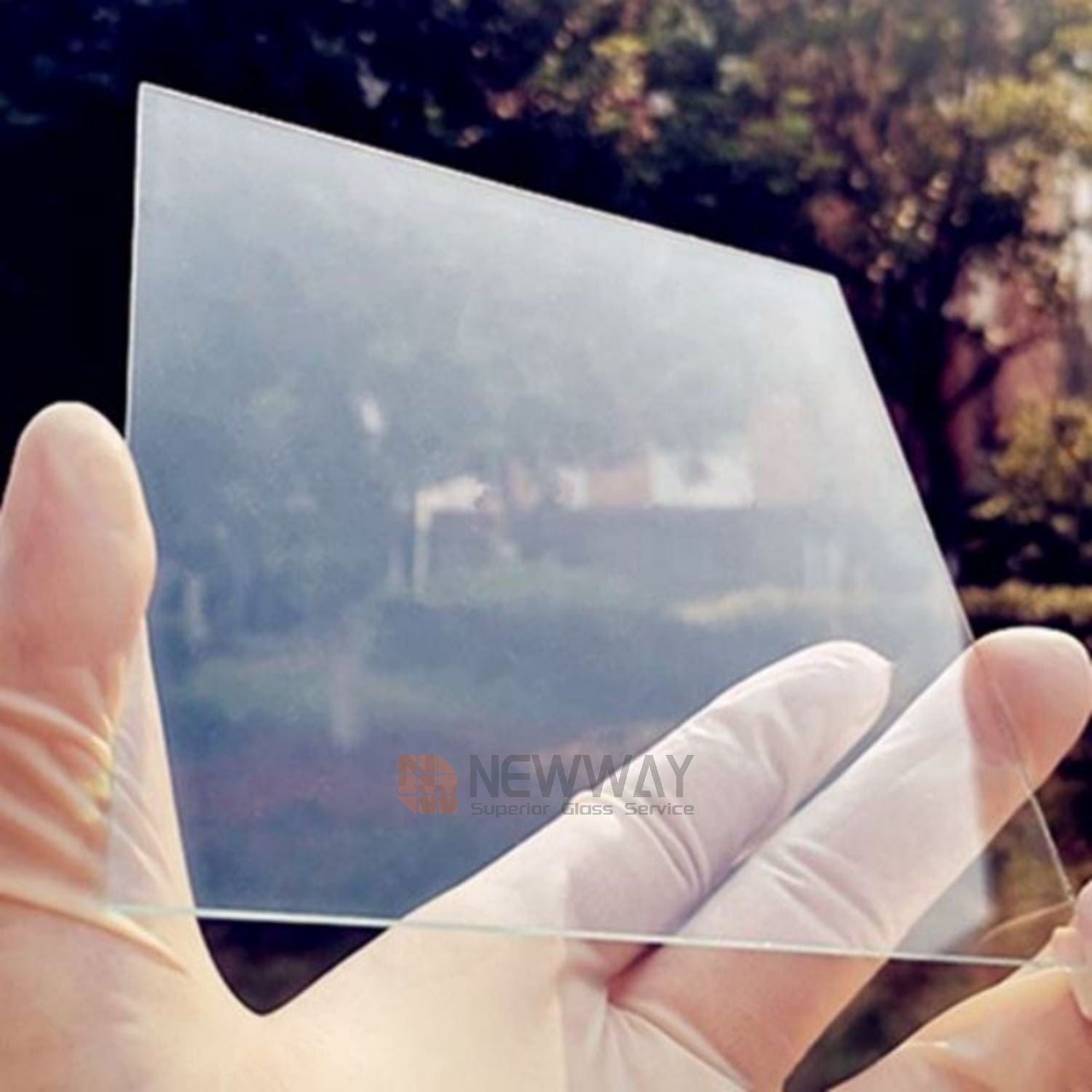

OEM White Printing Coated Chemical Strengthened Cover Glass For Elevator

Short Description

| FOB Price : | $0.5 - 9,999 / Piece |

| Min. Order Quantity : | 100 Piece/Pieces |

| Shape: | Rectangular |

| Size and Thickness: | 0.5mm-10mm |

| Glass material: | Clear Glass |

| Technical specifications: | AR/AG/AF Coating |

| Manufacturing process: | Board Cutting,Smooth Edge,Silk Screen Printing, Chemical Strengthened |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Port: | Shenzhen |

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Product Details

Key Features:

Packaging:

Step 1: PE film coating(Normally) / paper(For sea shipment prevent wet).

Step 2: Kraft paper for fixation.

Step 3: Carton for glass safety protection.

Step 4: Custom make plywood case with hinge for custom(fumigation + convenient inspection) convenience.

Step 5: Packing strap for further fixation.

Port: Shenzhen or Hongkong

PROCESS OF CUSTOMIZING PRODUCTS

CONSULTATION & DESIGN

PRODUCTION PLANNING

MANUFACTURING

PACKAGING & SHIPPING

AFTER-SALES SERVICE

FAQs

Do you provide custom glass solutions?

Yes, we specialize in providing customized glass solutions. Our OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services allow us to tailor glass products to meet your specific needs and requirements.

How to get a quote?

You can get a quote by contacting us via email or other provided contact methods. Please send us the product details, including the design (PDF or CAD file/AI file if available), quantity, and any other relevant information. Our team will review your request and provide you with a detailed quote as soon as possible.

What is the lead time for orders?

For samples, the lead time is typically 10-14 days. For mass production, it usually takes 12 to 20 days, depending on the product specifications and complexity. For more precise timelines, please contact our sales team.

Do you accept free sample service?

If you want reference samples, we may supply stock glass for free.There will be a sample charge for customizing, however this will be returned if a large order is completed.

Can I visit your manufacturing facilities?

Yes, we welcome visits to our manufacturing facilities. Please contact us to schedule a visit, and we will be happy to arrange a tour for you.