AR glass (Anti-Reflective Glass) is a functional glass that undergoes special processing to significantly reduce surface reflectivity and enhance light transmittance. This article provides an in-depth analysis of the optical principles, production processes, and key performance parameters of AR glass.

1. Core Principles of AR Glass: How Does It Suppress Reflection?

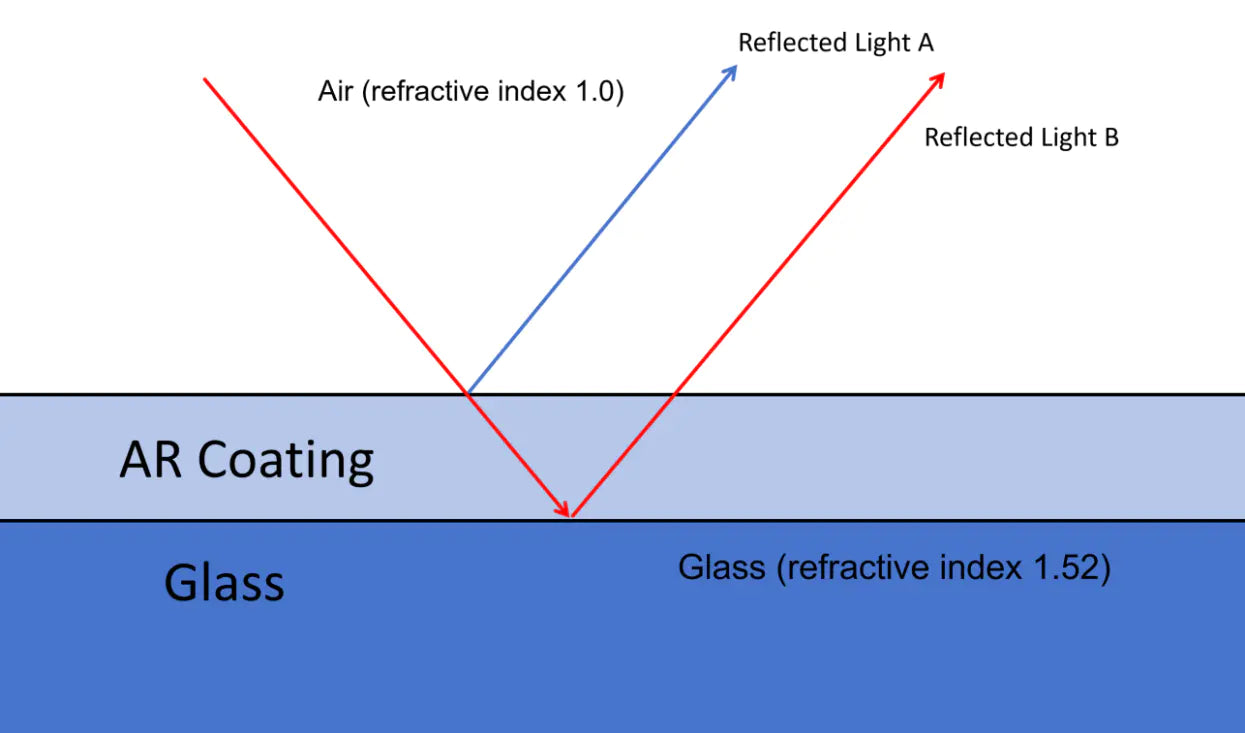

When light travels from air (refractive index 1.0) to glass (refractive index 1.52), reflection occurs at the glass surface due to the difference in refractive indices (natural light reflection on ordinary glass is about 4%-8%). The primary goal of AR glass is to counteract or weaken this reflection through technical means, primarily achieved via two optical mechanisms:

1.1 Thin-Film Interference: Canceling Reflected Light

When light strikes the AR coating on the glass surface, two reflections occur:

First reflection: Light reflects off the air-to-coating interface (Reflected Light A).

Second reflection: Light passes through the coating and reflects off the coating-to-glass interface (Reflected Light B).

By precisely controlling the coating thickness and refractive index, the two reflected beams undergo destructive interference (optical path difference of half-wavelength), drastically reducing reflectivity (single-layer coating can achieve 1%-2%).

1.2 Refractive Index Gradient Matching

The large refractive index difference between air (n=1.0) and glass (n=1.52) causes significant reflection. AR coatings introduce one or more intermediate refractive index layers (e.g., n=1.2-1.4) to create a gradient transition (air → AR coating → glass), minimizing interfacial reflection.

A single-layer AR coating with an ideal refractive index (√(1.0×1.52)≈1.23) can reduce reflectivity to 1%-2%.

Multilayer AR coatings with graded refractive indices can further reduce reflectivity to below 0.1%.

2. Three Major Manufacturing Processes for AR Glass

AR glass is primarily manufactured using Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and the Sol-Gel method. PVD includes magnetron sputtering—where a magnetic field confines electrons to bombard a target, creating dense, strongly adherent films with nanometer-level thickness control for high-end, multilayer AR coatings—and vacuum evaporation, a simpler, low-cost process suitable for single-layer, low-reflectivity coatings.

CVD forms oxide films on glass through chemical reactions of gaseous precursors on the surface. It offers excellent bonding strength, uniformity, and hardness enhancement under high temperatures, making it ideal for mass production in architectural glass and solar panels, balancing anti-reflection with durability.

The Sol-Gel method dissolves metal alkoxides in solvents to create sols, which are applied via spraying, dipping, or spin-coating and then cured to form oxide films. With low equipment cost and process flexibility, it is suitable for complex multilayer structures but has lower density and scratch resistance compared to PVD/CVD, often used for customized or low-cost AR glass such as smartphone screen protectors and display case glass.

3. Typical Applications

Displays: Smartphone screens, monitors, TV panels, VR/AR lenses.

Optical Instruments: Microscopes, telescopes, camera lenses.

Specialized Uses: Museum display glass (reducing glare), photovoltaic glass (enhancing light absorption), automotive windshields (minimizing night glare).

4. Conclusion

AR glass leverages thin-film interference and refractive index gradient matching to minimize reflection and maximize transmittance, making it a critical material in modern displays, optics, and energy sectors. Its manufacturing processes (PVD, CVD, Sol-Gel) each offer unique advantages, catering to varying demands for durability, precision, and cost. With ongoing improvements in transmittance (>95%) and reflectivity (≤0.5%), AR glass is widely used in high-end displays, optical instruments, solar modules, and smart vehicles, driving advancements in visual experience and energy efficiency.

We will provide you with the highest quality glass solutions.

What Is Tempered Borosilicate Glass to DIN 7080 and Where Is It Primarily Used?

DIN 7080 tempered borosilicate glass combines exceptional strength, thermal stability, and chemical resistance. Widely used in reactors, sight glasses, and lab equipment, it ensures safety and clarity under extreme conditions.

Unveiling the "King of Glass": How Tempered Borosilicate Glass is Reshaping Our Daily Lives

Tempered borosilicate glass—nicknamed the “King of Glass”—combines high strength, thermal stability, and chemical resistance, making it ideal for daily use, laboratory gear, optical components, and more.

Customized ITO/FTO Conductive Glass in Scientific Research Experiments

Customized ITO / FTO conductive glass plays a crucial role in scientific experiments, offering excellent conductivity, transparency, and stability. Ideal for photovoltaics, sensors, and analytical instruments.

Scientific Analysis and Influencing Factors of Glass Fogging Phenomenon

Customized ITO/FTO Conductive Glass in Scientific Research Experiments